HCHCR-D3

STANDARDS : X210CRW12

HCHCR-D3

DIN 2080

AISI D3

AFNOR Z210CW12-01

| C 2.00 | Si 0.30 | Mn 0.30 | Cr 12.00 |

Bharat Metal is the largest Supplier & Stockiest of HCHCR-D3 Steel in India.

D3 Steel Having 12 % ledeburitic chromium tool steel with great wears resistance .

Basically utilized as cutting tools for sheets up to 4 mm thickness, trimming dies, blanking dies for paper and plastics, shear cutting edges and rotational shear edges for sheet thicknesses up to 2 mm.

Steel Properties

D3 Steel having properties of High Carbon 2% and High chromium 12 % tool steel with high wear resistance. Its supply condition is normally annealed to easy machining which recommended hardness is 57-58 HRC after making the dies & tools.

Physical Properties

| Coefficient of thermal expansionat °C | 20-100 | 20-200 | 20-300 | 20-400 | 20-500 | 20-600 | 20-700 |

|---|---|---|---|---|---|---|---|

| 10-6 m/(m*K) | 10.7 | 11.6 | 12.3 | 12.6 | 12.9 | 13.2 | 13.3 |

| Thermal Conductivity °C | 20 | 350 | 700 |

|---|---|---|---|

| W/(m*K) | 16.6 | 20.5 | 24.3 |

Application

HCHCR D3 is used in cold Dies & tooling application that required the achievement of high degree of accuracy in hardening & tempering, such as dies drawing, forming cold rolls, powder metal tooling and blanking and trimming dies, blanking dies for paper and plastics, shear blades , cold die punches , Ejector pins etc.

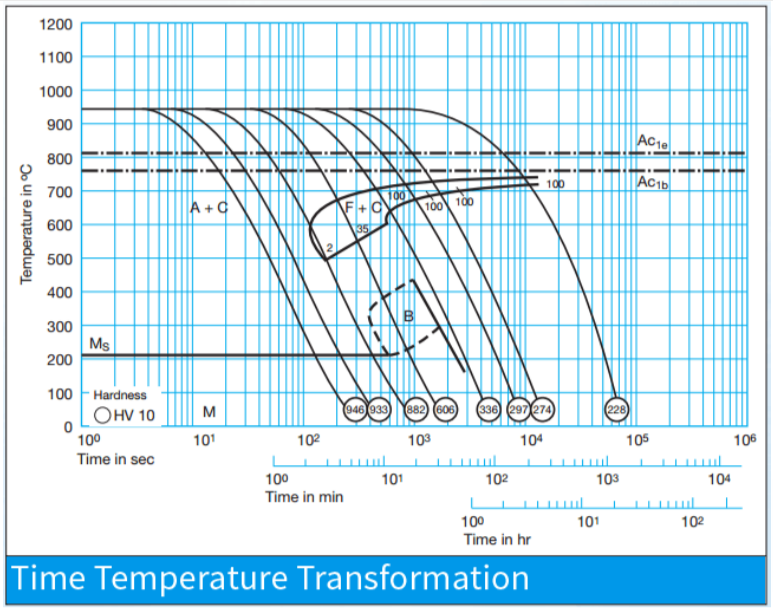

Heat Treatment

| Soft annealing °C | Cooling | Hardness HB |

|---|---|---|

| 810 – 850 | Furnace | max. 250 |

| Stress-relief annealing °C | Cooling |

|---|---|

| approx. 670-720 | Furnace |

| Hardening °C | Quenching | Hardness after quenching HRC |

|---|---|---|

| 940 – 970 | Oil | 64.5 |

| Hardening °C | Quenching | Hardness after quenching HRC |

|---|---|---|

| 940 – 970 | Oil | 64.5 |

| 950-980 | Air (up to 30 mm thickness) | 64.5 |

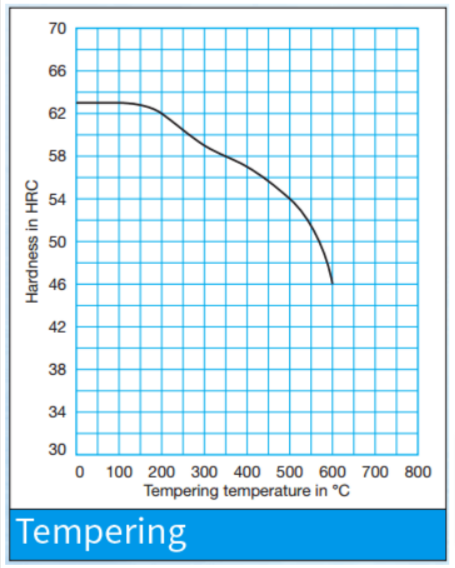

| Tempering °C after Quenching | 100 | 200 | 300 | 400 | 500 | 600 |

|---|---|---|---|---|---|---|

| HRC | 63.5 | 61.5 | 58 | 57.5 | 55 | 47 |