M35

STANDARDS : X100CRMOV5

M35

DIN 3243

AISI M35

AFNOR Z85WDCV06-05-04-02

| C 0.92 | Cr 4.10 | Mo 5.00 | V 1.90 | W 6.40 | Co 4.80 |

Bharat Metals is the leading Supplier & Stockiest of M35 Steel in India.

M35 is cobalt content material in these high-performance excessive-speed steel results in high pink hardness and tempering resistance. As a final result, this grade is primarily suitable for conditions involving thermal stresses and discontinuous cutting.

This grade is typically used as heavy-duty milling cutters of every kind, particularly stressed twist drills and taps, profile knives, machining of high-strength substances, broaches

Steel Properties

The cobalt content in this high-performance high-speed steel results in high red hardness and tempering resistance. As a consequence, this grade is particularly suitable for conditions involving thermal stresses and discontinuous cutting. Under the name Rapidur 3245, AISI M 35 + S and material number 1.3245, this steel grade is supplied with a higher sulphur content (S = 0.10 %).

Application

Heavy-duty milling cutters of all kinds, highly stressed twist drills and taps, profile knives, machining of high-strength materials, broaches.

Heat Treatment

| Soft annealing °C | Cooling | Hardness HB |

|---|---|---|

| 820 – 860 | Furnace | max. 269 |

| Stress-relief annealing °C | Cooling |

|---|---|

| 630 – 650 | Furnace |

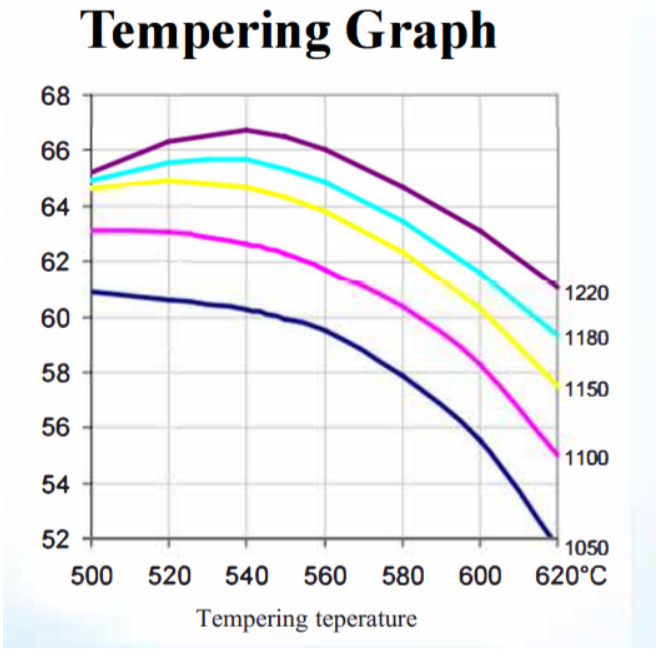

| 1st pre-heating °C | 2nd and 3rd | Hardening °C | Quenching | Tempering °C | Hardness after Teperature HRC |

|---|---|---|---|---|---|

| up to approx. 400 in an air-circulating furnace | 850 and 1050 | 1190 – 1230 | Saltbath, at least 550 °C Oil ,Air | at least twice 540-570 | 64 – 67 |

1 For cold-forming tools with a complex geometry, a hardening temperature at the lower end of the quoted range is recommended. The stated hardening temperatures apply to saltbath hardening only. For vacuum hardening, we suggest a reduction of 10 °C to 30 °C. |