T1

STANDARDS

T1

DIN 3355

AISI T1

Bharat Metals is the leading Supplier & Stockiest of T1 Steels.

T1 is a tungsten kind tool steel. Very high resistance to put on and to softening. Just right longevity, reducing potential & deep hardening response. This grade is on the whole used for turning, planning & slotting instruments, tapes, twist drill, threading dies, profile slicing instruments, broaching instruments & reamers.

Steel Properties

Standard hiqh-speed steel qrade. Itswell-balanced alloycomposition forms the basis of its high_touqhness and good clll:ting edge retention, render’lng it suitable for a large variety of applications.

Physical Properties

| Thermal Conductivity at °C | 20 | 350 | 700 |

|---|---|---|---|

| W/(m*K) | 32.8 | 23.5 | 25.5 |

Application

For all metal-cutting tools for roughing or finishing such as twist drills, diverse milling cutters, thread dies, broaches, reamers, countersinks, thread chasers, circular saw segments, shaping tools and woodworking tools. Also highly suitable for cold-forming tools such as cold extrusion rams and dies, as well as cutting and precision cutting tools, plastic moulds with elevated wear resistance and screws.

Heat Treatment

| Soft annealing °C | Cooling | Hardness HB |

|---|---|---|

| 870-900 | slowly | max. 270 |

| Stress-relief annealing °C | Cooling |

|---|---|

| 630 – 650 | Furnace |

| 1st pre-heating °C | 2nd and 3rd | Hardening °C | Quenching | Tempering °C | Hardness after Teperature HRC |

|---|---|---|---|---|---|

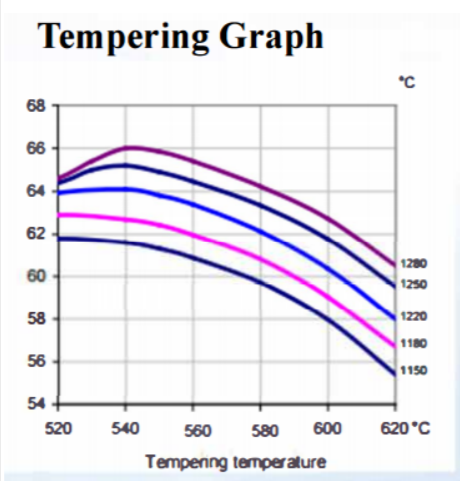

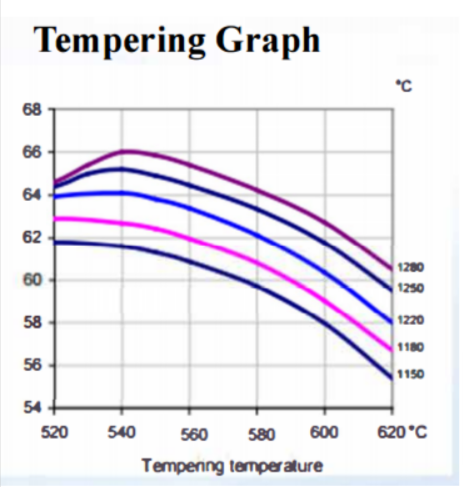

| up to approx. 400 in an air-circulating furnace | 850 and 1050 | 1190 – 1230 | Saltbath, at least 550 °C Oil ,Air | at least twice 530-560 | 64 – 66 |