H13

STANDARDS : X40CRMOV5

H13

DIN 2344

AISI H13

AFNOR Z40CDV5

| C | Si | Mn | P | S | Cr | Mo | V |

|---|---|---|---|---|---|---|---|

| 0.35-0.42 | 0.90-1.20 | 0.30-0.50 | <0.03 | <0.004 | 4.90-5.40 | 1.20-1.40 | 0.90-1.10 |

H13 tool steel is the most popular steel grade for various Industries. The main features of high alloyed Cr-Mo-V Hot Work tool steel is high wear resistance to thermal shock and to heat cracking, good mechanical characteristics & toughness in hot condition.H13 appears excellent machinability with constant hardness during production activities. The equivalent steel grade H-13 / SKD61 / AISI H13 normally available in the annealed condition but in some specific applications, we provide Pre-Hard H13 with its standard hardness 460-500 BHN. Utilized for ejector pins, apparatus holders and shrink fit chucks.

H13 ESR

ESR is the most refined material with the traditional VD route. The quality of material increase the toughness, highly increase the micro- cleanness level.Highly recommend the use of AISI-H13 ESR grade for Aluminum Pressure Die Casting & other component subjected to high working temperatures and high pressure strength. H13 is fully ultrasonic inspected with 100% positive results as per NDT standards.

H13 Steel Properties

High hot-wear resistance and hot tensile strength as well as good toughness, thermal conductivity and insusceptibility to hotcracking. Can be water-cooled to a limited extent.

Mode of Supply

Bharat Metals are largest stockiest and supplier of H13 tool steel in flat, square and round bar. We provide steel in all sizes as your requirements. H13 die steel is available in flat, square and round shape. Consult our team who will assist you for h13 steel query.

H13 Physical Properties

| Coefficient of thermal expansionat °C | 20-100 | 20-210 | 20-300 | 20-400 | 20-500 | 600 | 700 |

|---|---|---|---|---|---|---|---|

| 10-4 m/(m*K) | 10.8 | 12 | 12.4 | 12.7 | 13.1 | 13.3 | 13.5 |

| Thermal Conductivity °C | 20 | 350 | 700 |

|---|---|---|---|

| W/(m*K)Annealed | 27.1 | 30.4 | 33.2 |

| W/(m*K) Quenched & Tempered | 25.4 | 27.7 | 30.4 |

Application

Dies for Drop Forgings , Aluminum / low Pressure Die Casting, Extrusion, Containers & liner, Punches, Plugs, Holdez , Injection moulds Etc.

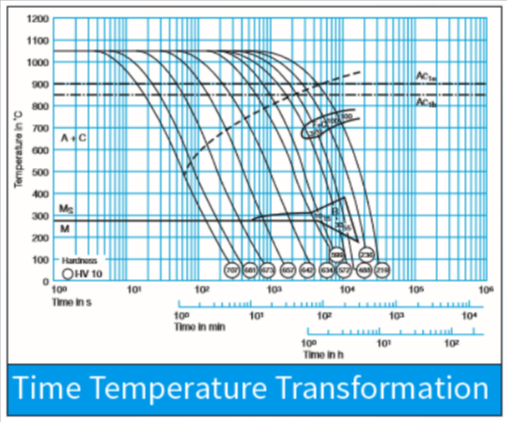

Heat Treatment

| Soft annealing °C | Cooling | Hardness HB |

|---|---|---|

| 760 – 810 | Furnace | max. 240 |

| Stress-relief annealing °C | Cooling |

|---|---|

| approx. 610 – 660 | Furnace |

| Hardening °C | Quenching | Hardness after quenching HRC |

|---|---|---|

| 1030 – 1060 | Air ,oil or saltbath, 500 – 550 °C | 55 |

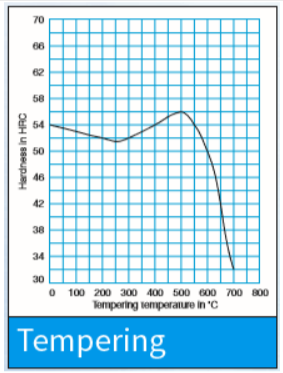

| Tempering °C | 100 | 210 | 300 | 400 | 500 | 550 | 600 | 650 | 700 |

|---|---|---|---|---|---|---|---|---|---|

| HRC | 54 | 53 | 53 | 55 | 56 | 54 | 51 | 43 | 34 |