P20+Ni

STANDARDS : 40CRMNNIMO8-6-4

P20+Ni

DIN 2738

AISI P20+Ni

| C 0.42 | Mn 1.50 | Cr 1.95 | Ni 1.10 | Mo 0.20 |

P20+Ni is specially used for Plastic injection die moulds. The characteristics of a material are right sharpening, photo-etching properties with high purity and good homogeneity. P20+Ni is upgraded version of plastic mold steel 0f 2311, which normally supply in Pre hardened condition. Hardness in as supplied condition 280-320 HB with having uniform hardness. The additional nickel content of 1 % increases through hardening. It has good machinability, suitable for Texturing, fine polishability, adequate corrosion resistance, vacuum-degassed steel.

P20+Ni High Hard ( HXM 24 )

P20+Ni is with High Hardness 360-400 BHN and increase alloy elements to get extra life and outstanding polishing.

Steel Properties

P20 +Ni is upgrade version of plastic mold steel 0f 2311, which normally supply in Pre hardened condition. Hardness in as supplied condition 280-320 HB. The additional nickel content of 1 % increases through hardening. It is micro-alloyed. It has good machinability, suitable for texturing, outstanding polishability, adequate corrosion resistance. vacuum-degassed steel with the following excellent features.

Physical Properties

| Coefficient of thermal expansionat °C | 20-100 | 20-200 | 20-300 | 20-400 | 20-500 | 20-600 | 20-700 |

|---|---|---|---|---|---|---|---|

| 10-6 m/(m*K) | 11.2 | 12.8 | 13.5 | 13.7 | 14.3 | 14.7 | 14.9 |

| Thermal Conductivity °C | 20 | 350 | 700 |

|---|---|---|---|

| W/(m*K)Annealed | 35 | 34 | 33 |

Application

P20+Ni is equivalent grade of most popular steel grade of DIN 2738 which is applicable for large & small plastic mould dies for Automotive Industries, Dies for Domestic goods , High finishing plastic Die, Boaster Plates of Presses, Die Holders & Shoe blocks for drop Hammers, Press Cassettes , Upsetter Blocker, forging dies, Different dies & mold for plastic products etc.

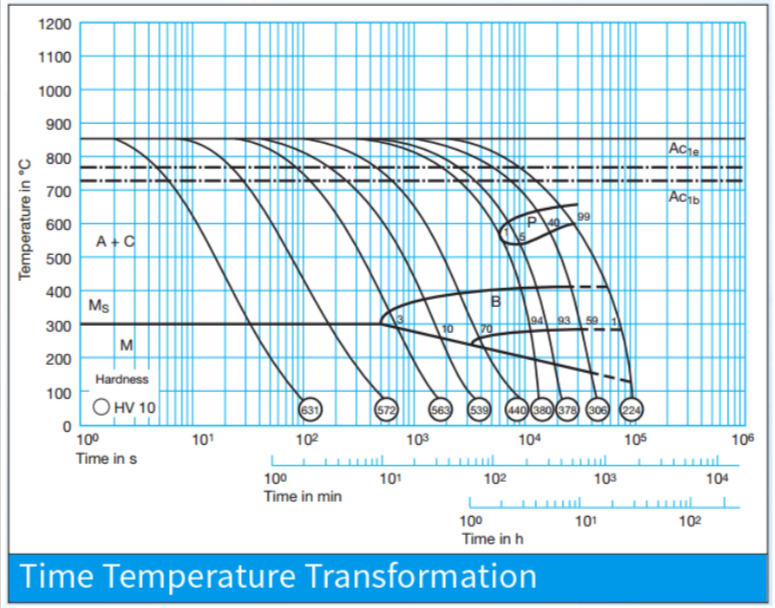

Heat Treatment

| Soft annealing °C | Cooling | Hardness HB |

|---|---|---|

| 710 – 740 | Furnace | max. 235 |

| Hardening °C | Quenching | Hardness after quenching HRC |

|---|---|---|

| 840 – 870 | Polymer or oil | 51 |

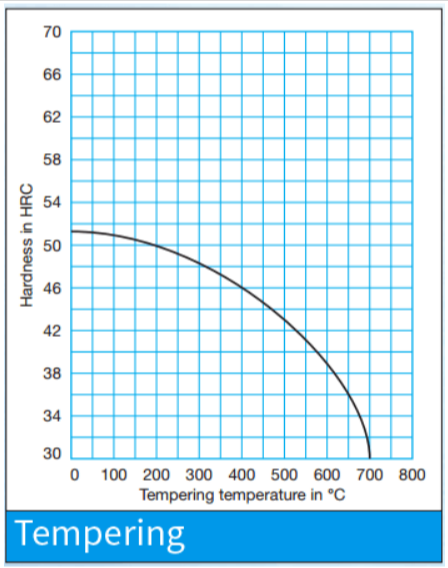

| Tempering °C after Quenching | 100 | 200 | 300 | 400 | 500 | 600 | 700 |

|---|---|---|---|---|---|---|---|

| HRC | 51.5 | 50.2 | 48 | 46.2 | 43 | 39 | 29 |